Preserving the building’s historic character was a top priority throughout the design process. To achieve this, two custom outdoor air handling units were integrated into a single cabinet, concealed within an architecturally appropriate enclosure. The design team also ensured full compliance with the University’s established standards for design, construction, and materials. Additionally, the renovation leveraged the campus’ existing chilled water and steam infrastructure, incorporating new heat exchangers and pumps to support the system. To enhance energy management, a range of metering devices were installed to monitor electrical power, water and gas consumption, lighting loads, and fan and pump energy usage. These systems were fully integrated into the building’s control system, allowing the University to effectively monitor performance and respond in real time.

The system provides lighting, power and fire alarm design. The lighting incorporates full LED design with daylight harvesting, compliance to ASHRAE 90.1 energy code with individual room control and dimming throughout the facility. Power includes multiple points of energy monitoring for different departments and a complete upgrade of the distribution switchgear in the existing portion of the building and new distribution throughout the addition portion. The fire alarm design was a voice system with smoke evacuation control for the Atrium area. Integrations with the exterior door operators and security system was needed to utilize the outside doors as the relief air for the smoke evacuation system in lieu of dampers and louvers. Generator emergency power was provided for life safety systems, technology systems, and key building functions and services. Power distribution consisted of three levels of surge protection for sensitive electronic equipment.

The plumbing project consisted of demolition, renovation and new construction with new plumbing piping system, plumbing fixtures and equipment provided throughout the building. The storm and sanitary drainage systems utilized gravity drainage to the building sewer where feasible with lifstation provided for sanitary, elevator pit discharge and subsoil building perimeter drainage systems located below the basement floor. The roof drainage consists of primary and secondary roof drains with separate piped discharge. Kitchen grease waste is discharge to above floor point of use grease interceptors. The new domestic water service includes metering, backflow prevention, pressure booster system, water softening system, boiler make up water and piping distribution systems consisting of domestic cold water, hot water and hot water return piping. Domestic hot water is supplied by a steam to water semi-instantaneous indirect water heater with electronic mixing valve. The natural gas service includes metering, pressure regulating and distribution piping to required mechanical equipment.

Fire Protection Systems design was a new water service is provided with a double check valve assembly and wet system riser serving the existing building and new area of construction. Standpipes are provided in required stairwells with fire department hose connections and floor control valves to supply each floor. Concealed sprinklers are provided where there are finished ceilings

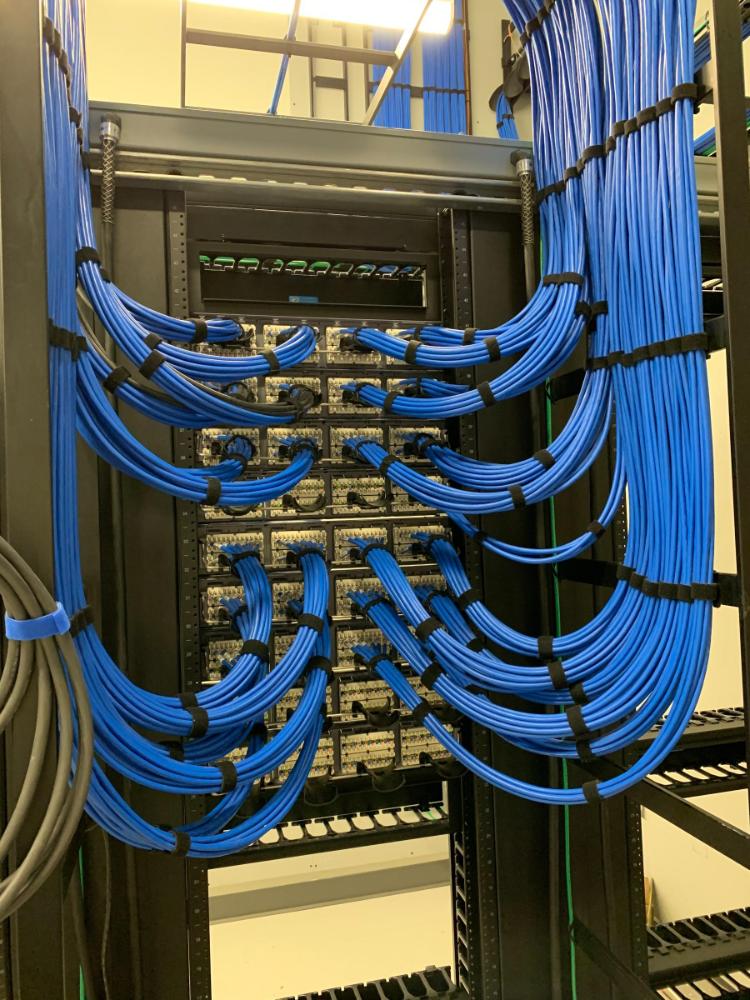

Provided full Technology Design and discipline lead/management for a complete Telecommunications design including structured cabling, pathways, Telcom room design, grounding, security system, access control, AV Systems, Network Electronics, and Wireless Network. Provided estimates for the $2 million AV systems for budgeting. Provided construction oversight, specifications, and interfaced with the Owner’s project management team, end users, architects, and engineering disciplines.